What is Timber?

- Timber, or simply wood, is the material making up the body of trees.

- Timber is widely used for its compressive strength, stiffness, toughness, accessibility and cost-effectiveness.

- As wood comes from trees, it is relatively sustainable, despite being difficult to recycle, as it is biodegradable and trees can be grown back.

Categorizing Wood

- There are lots of different types of wood, each with different properties.

- Timber can be categorized into:

- hardwood

- softwood

- bamboo (bamboo is actually a family of grasses, but it shares many properties with woods!)

- solid wood

- man made/engineered timber

- fresh wood

- recovered/recycled wood

Hardwood

- Hardwood is a wood type that grows from deciduous trees, which means they are leaf-bearing and lose their leaves during the winter.

- This usually applies to trees that grow around the equator and moderate zones of the planet.

- As they grow slower, grains are denser and tightly packed, and they are harder to replenish/regrow.

- They are tougher and harder to manipulate than most softwoods.

- As the grains are denser, hardwood is less absorbent than softwood.

Softwood

- Softwood is a wood type that grows from pine trees, which means they carry needles and have leaves all-year.

- This usually applies to trees that grow around the subpolar and temperate zones of the planet.

- As they grow faster, grains are less dense and loosely packed, and they are easier to replenish/regrow.

- They are less tough and easier to manipulate than most hardwoods.

Bamboo

- Bamboo is not a wood type but can be considered one when designing.

- It is in fact a type of fast growing grass.

- They grow in moderate, subtropical and tropical zones.

- They grow even faster than softwoods, so they are even easier to replenish/regrow.

- Some species of bamboo have been recorded growing up to 120 centimeters in a day!

- Bamboos can spread very quickly and can even grow in sub-par soil.

- They are very tough and can withstand great tensile and compressive forces.

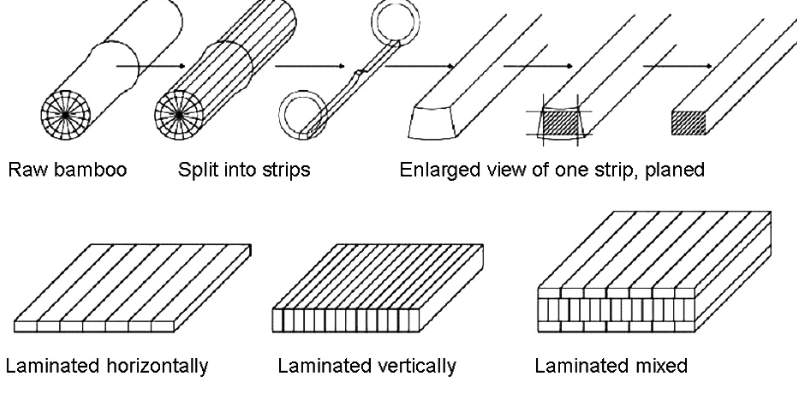

- They need specific manipulation to create sheets, rods and tubes for construction.

Engineered Timber

- Man-made, or engineered timber is modified in some way or for from the original timber.

- Unlike solid wood, which is cut from trees in one piece, man made timber consists of layers or particles of solid wood, that are embedded in glue.

- This is why they can also be considered a composite.

MDF Board

- MDF is particle based: wood dust is glued and compressed to a panel.

- It’s dimensionally stable and easy to manipulate, but lacks a lot of qualities and needs finishing.

- MDF is often used for simple shelves and cupboards.

Chip Board

- Chip board consists of wood shavings, glued and compressed to panels. They have some benefits of solid woods, as it contains shavings with intact wood grains in it.

- They can be used in flooring, and are often laminated to be used for cheap furniture, like IKEA kitchen panels.

Plywood

- Laminate/ply boards have the best properties of man made timber, as it consist of cross laminated sheets of solid wood.

- By alternating sheet (thus grain) directions, it increases in strength and rigidity.

- Different types of wood (hard and soft) can also be alternated to achieve better results.

- Laminated board is applied to flooring, roofing, structures, stands etc.

Wood Life Cycle and Treatment

Harvesting and Treating

- Growing rates differ between tree types.

- Harvesting/cutting is/can be performed illegally, mostly in tropical areas.

- When done more sustainably, every cut tree is replenished at an equal rate (reforestation).

- Cutting then happens selectively and responsibly, so no fields/forests are cleared all at once.

- FSC is a stewardship label that guarantees the origin of the wood.

- Harvested wood needs to then be cut from gross sizes to net sizes.

- These are internationally standardized.

- Theoretical net sizes can vary (tolerance) a few mm in reality.

- Cut wood needs to go through a drying process to achieve its EMC (moisture balance).

- Wood can be ((semi-)open) air dried and/or kiln dried ((non-)heated).

- Drying happens to release free and absorbed moisture.

- EMC level means the wood is dimensionally stable and predictable in use.

Distortions

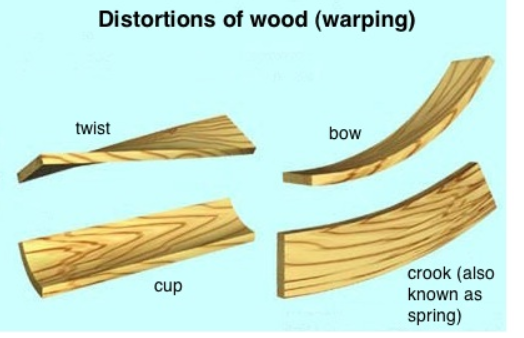

- Wood has natural and artificial ‘defects’, like knots, resin, bowing, cupping, twisting and warping.

- Knots and resin are naturally present elements in wood, as they refer back to their origin as a tree.

- Warping, cupping, twisting happens due to undesired growth direction inside the wood, along with imperfect conditions during drying/kilning.

- This is why only perfectly straight trees are selected for A-class wood.

- B quality wood will see more knots and deformations.

- Resin tends to be a bigger problem in soft woods than in hard woods.

- Knots, caused by branches, form holes in the grain of the wood, and can fall out, leading to unwanted holes.

Wear on Wood

- Untreated wood is more subjected to wear and tear, and weather conditions.

- Impacts, UV and moisture affect wood in multiple ways, basically causing rot and deterioration.

- The correct treatment/finishing happens for aesthetics and protection.

- Wood can be sanded, cut, glued, painted, varnished, oiled, waxed, pressure treated and creosoted (fully impregnated wood e.g. garden fencing, furniture, decking, etc…).

- Paints, varnishes and creosoting adds polymer based chemicals to the wood, making them harder to recycle.

Recovering Wood

- For a high wood recycling rate, a number of things need to be optimised:

- Wood recovery

- Used/discarded wood needs to be recovered, collected and sorted correctly.

- Unrecovered wood will decay or be incinerated.

- Wood recovery

Joining Methods

Nails

- An old fastening method, using a smooth metal pin that is hammered into the wood to secure two parts together.

- Hard to undo, can slide off over time, allows rotation of parts.

Screws

- Threaded, tapered ‘nails’, a spiralling outer rim drives the screw into the wood, joining one or multiple parts together.

- Easier to undo, does not allow slipping and to an extent rotation.

- Screws have different types of heads and a pointy tip to drive into the wood (or plastic, metal etc.)

Nuts and Bolts

- Also threaded, but only to be connected with a nut on the other end of the wood, not to drive into wood.

- This secures panels of wood, without damaging the wood.

Wood Glue

- Strong glue that creates very strong bonds between wooden parts.

- Hard to undo, irreversible.

Wooden Joints

- A large range of wood joints exists, ranging from slotting to dowel joints, finger joints, mortise and tenon joints, etc.

- Disassemblable, but can also be secured with supportive glue.

Metal fittings

- Metal fittings can be used for additional support.

Glossary

Wood Types

- Hardwood

- Wood from a deciduous tree.

- The slower growth of the tree makes the wood more dense and stiff.

- Softwood

- The wood from a coniferous (evergreen) tree.

- The faster growth of the tree makes the wood less dense and softer.

- Laminated boards

- Sheets of material made from layers of veneers (e.g. plywood)

- Man-made timber

- Also known as engineered wood or composite wood.

- Wood products that are made by binding or fixing strands, particles of fibers, veneers of boards of wood together with adhesives or other fixing methods to create composite materials.

- Typical examples include MDF, plywood and chipboard.

- Particle boards

- A material made from different sizes of wood chips and joined with glue.

Properties

- Absorbed moisture

- The moisture within timber that is contained in the cells walls.

- Equilibrium Moisture Content (EMC)

- EMC the moisture content where wood achieves an equilibrium with the environment

- Can be affected by humidity and temperature.

- Free moisture

- The moisture within timber that is contained within the cell cavities and inter-cellular spaces.

Treating

- Air-drying

- Air-drying places the stacks of sawn timber in the open or in large sheds hence there is little control over the drying process.

- Creosote

- A material that penetrates the timber fibers protecting the integrity of the wood from from borers, wood lice and fungi.

- Kiln-drying

- Kiln-drying places the stacks of cut timber in a kiln, to reduce the moisture content in wood, where the heat, air circulation, and humidity is closely controlled

- Kiln-seasoning

- Thermally insulated chamber, a type of oven, which produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes.

- Lamination

- Covering the surface of a material with a thin sheet of another material typically for protection, preservation or aesthetic reasons.

- Seasoning

- Seasoning is the commercial drying of timber which reduces the moisture content of wood.

Distortions

- Warping

- A distortion in wood caused by uneven drying, which results in the material bending or twisting.

- Bowing

- A warp along the length of the face of the wood

- Cupping

- A warp across the width of the face of wood, in which the edges are higher or lower than the center.

- Knots

- Imperfections in timber, caused by the growth of branches in the tree that reduces its strength.

- Twisting

- A distortion in which the two ends of a material do not lie on the same plane.

Wear

- Dry rot

- When timber is subject to decay and consumption by fungus.

Sustainability and Environment

- Reforestation

- Reforestation is the process of restoring tree cover to areas where woodlands or forest once existed.

- If this area never returns to its original state of vegetative cover the destructive process is called deforestation.

- Wood recycling

- Wood recycling is the process of turning waste timber into usable products.

- Recycling timber is a practice that was popularized in the early 1990s as issues such as deforestation and climate change prompted both timber suppliers and consumers to turn to a more sustainable timber source.

- Wood treatment

- Treatment of wood can involve using solutions, which make the wood poisonous to insects, fungus, and marine borers as well as protecting it from the weather.