Nature of Plastics' Design

- Most plastics are produced from petrochemicals.

- Bio-plastics are being developed due to:

- The finite nature of oil reserves

- The threat of global warming

- Bio-plastics degrade upon exposure to factors such as:

- Sunlight, water, or dampness.

- Bacteria, enzymes, wind erosion, and, in some cases, consumption by insects.

- In most cases, degradation does not lead to the complete breakdown of plastic.

- Designers must consider the moral, ethical, and environmental implications when selecting materials.

Examples of Plastics

Purpose and Properties of Plastic

- Many plastics were invented, often by accident, to meet specific needs:

- Withstand pressure, heat, transport, skin contact, acids, and impacts.

- Plastic introduced possibilities not achievable with traditional materials (wood, iron, stone).

- Plastics have become integral to daily life.

Categorizing Plastics

Thermoplastics

- Thermoplastics are chemically recyclable and can be melted and cooled into a new form.

- Thermoplastics are the most commonly used type of plastic.

- They are composed of long linear chains of molecules, called polymers.

- The main feature that sets them apart from thermosets is their ability to go through numerous melt and solidification cycles without significant degradation.

- Thermoplastics are usually supplied in the form of small pellets or sheets that are heated and formed into the desired shape using various manufacturing processes.

- The process is completely reversible, as no chemical bonding takes place, which makes recycling or melting and reusing thermoplastics feasible.

- Features of thermoplastics:

- Can be reheated and reshaped.

- Good impact resistance and toughness.

- Easily processed by injection molding, blow molding and vacuum molding.

- Lower thermal resistance

- Can be easily recyclable.

- Examples of thermoplastics:

- Acrylic (PMMA)

- Acrylonitrile butadiene styrene (ABS)

- Polyamide (PA)

- Polylactic acid (PLA)

- Polycarbonate (PC)

- Polyether ether ketone (PEEK)

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

Thermosetting Plastic

- In contrast with thermoplastics, thermosetting plastics (also referred to as thermosets) remain in a permanent solid state after curing.

- Polymers in thermosetting materials cross-link during a curing process that is induced by heat, light, or suitable radiation.

- This curing process forms an irreversible chemical bond.

- Thermosetting plastics decompose when heated rather than melting, and will not reform upon cooling.

- Recycling thermosets or returning the material back into its base ingredients is not possible.

- Examples of Thermoset Plastics:

- Cyanate ester

- Epoxy

- Polyester

- Polyurethane

- Silicone

- Vulcanized rubber

Single-Use Plastics

- Single-use plastics, as per their name, are only used once.

- They have very short product lifespans and are generally thrown away once it is over.

- Common in packaging and targeted for replacement by alternative materials (supported by global legislation).

- Features of thermosets:

- Set permanently when heated, cannot be remolded.

- Very high thermal resistance.

- Strong and durable.

- Good electrical insulators.

- Difficult to recycle.

- Excellent dimensional stability.

- Chemical resistance.

- Examples of applications of single-use plastics include:

- Plastic cups

- Plastic straws

- Grocery bags

- Bubble wrap

- Packaging peanuts

Durable Plastics

- Used in long-lasting applications like furniture and are harder to replace in daily life.

- Examples of applications of durable plastics:

- Furniture

- Toys

- Car interiors

Future Challenges with Plastic

- Petrol-based virgin plastic is a finite resource:

- The question is how society will perceive plastic: as waste or as a resource?

- A shift is required from a make-use-dispose mindset to rethink and reuse, which is difficult due to existing habits.

Recycling Complexities

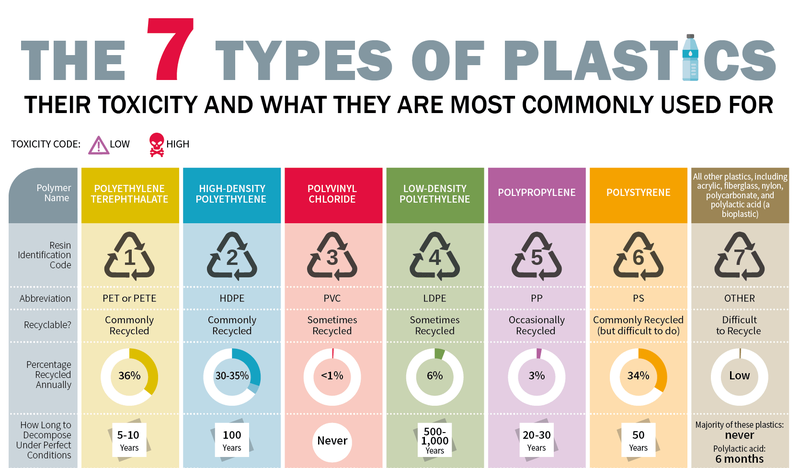

- Plastics may appear similar but differ chemically, making recycling challenging:

- Mixing chemically unrelated materials (e.g., wood and glass) results in unusable resources, as with plastics.

- Some plastics are chemically related and recyclable, while others are not.

Recycling challenges

Issues with Recycling

- Recycling does not fully address the issue of virgin material dependency.

- The invention of mixed plastics creates additional complexity in achieving chemical purity for reuse.

- There is a significant challenge for humanity and the industry to innovate sustainable plastic solutions.

Properties and Uses of Various Thermoplastics

- You don't need to memorize all these.

Acrylic (PMMA)

Physical

- Transparent

- Rigid

- Lightweight

Mechanical

- Moderate hardness

- Moderate impact resistance

Uses

- Displays

- Signs

- Optical lenses

- Automotive lights

Advantages

- Excellent clarity

- UV resistant

- Weatherproof

Acrylonitrile Butadiene Styrene (ABS)

Physical

- Rigid

- Tough

Mechanical

- Strong impact resistance

- Moderate hardness

Uses

- Consumer electronics

- Automotive parts

- Plumbing

Advantages

- Easy to mold

- Tough at low temperatures

- Good dimensional stability

Polyamide (PA) / Nylon

Physical

- Strong

- Durable

- Somewhat flexible

Mechanical

- Excellent wear resistance

- High strength

Uses

- Gears

- Automotive parts

- Clothing

- Electrical components

Advantages

- High toughness

- Wear-resistant

- Can be reinforced with fibers

Polylactic Acid (PLA)

Physical

- Rigid

- Biodegradable

- Semi-transparent

Mechanical

- Moderate strength

- Low impact resistance

Uses

- 3D printing

- Food packaging

- Disposable items

Advantages

- Made from renewable resources

- Biodegradable

- Low environmental impact

Polycarbonate (PC)

Physical

- Transparent

- Tough

- Impact-resistant.

Mechanical

- Very high impact resistance

- Moderate hardness.

Uses

- Eyewear lenses

- Optical discs

- Automotive parts

- Safety gear.

Advantages

- Extremely strong

- Optical clarity

- Flame retardant

Polyether Ether Ketone (PEEK)

Physical

- Rigid

- High-temperature resistance

Mechanical

- Very high strength

- Tough

- Low friction

Uses

- Aerospace

- Automotive

- Medical implants

- Electrical insulation

Advantages

- Extremely high heat resistance

- Excellent chemical resistance

- Wear-resistant

Polyethylene (PE)

Physical

- Flexible

- Lightweight

- Low-density

Mechanical

- Moderate strength

- High impact resistance

Uses

- Packaging

- Pipes

- Toys

- Containers

Advantages

- Easy to process

- Resistant to chemicals

- Low moisture absorption

Polypropylene (PP)

Physical

- Lightweight

- Flexible

- Resistant to fatigue

Mechanical

- Moderate strength

- Good impact resistance

- Uses: Packaging, automotive parts, textiles, medical supplies.

- Advantages: Low density, high chemical resistance, easy to mold.

Polyvinyl Chloride (PVC)

Physical

- Rigid or flexible, depending on the formulation

Mechanical

- Moderate to high strength

- Can be either flexible or rigid

Uses

- Pipes

- Flooring

- Medical tubing

- Electrical insulation

Advantages

- Versatile

- Resistant

- Chemicals

- Cost-effective

Properties and Uses of Various Thermosetting Plastics

Cyanate Ester

Physical

- Rigid

- Thermoset resin

- Highly resistant to heat and chemicals

Mechanical

- Very high strength

- Excellent dimensional stability

- Low moisture absorption

Uses

- Aerospace components

- High-performance electronics

- Automotive parts

Advantages

- Superior thermal stability

- High electrical insulation properties

- Resistant to harsh environments

Epoxy

Physical

- Hard, rigid, and tough

- Can be formulated for flexibility

Mechanical

- Excellent bonding strength

- Good fatigue resistance

- High tensile strength

Uses

- Adhesives

- Coatings

- Composite materials

- Electrical encapsulation

- Structural components

Advantages

- Superior adhesion

- High mechanical properties

- Chemical resistance

- Excellent durability

Polyester

Physical

- Rigid

- Lightweight

- Somewhat flexible

Mechanical

- Moderate strength

- Impact resistance

- Less durable compared to epoxy

Uses

- Fiberglass-reinforced composites (boats, car parts)

- Resin for molds

- Surface coatings

- Clothing

Advantages

- Cost-effective

- Easy to process

- Good corrosion resistance

Polyurethane

Physical

- Can be rigid or flexible depending on formulation, durable.

Mechanical

- Excellent abrasion resistance, high strength, and flexibility.

Uses

- Foam (e.g., mattresses, insulation), coatings, adhesives, automotive parts, footwear.

Advantages

- Versatile (rigid or flexible), high wear resistance, impact resistance, good thermal insulation.

Silicone

Physical

- Flexible

- Heat-resistant

- Rubber-like, but can also be rigid.

Mechanical

- Low tensile strength

- Excellent elongation and flexibility.

Uses

- Seals

- Gaskets

- Medical implants

- Electronics

- Kitchenware

Advantages

- Extremely heat-resistant

- Flexible

- Chemically inert

- Non-toxic

- Great for sealing and insulation