- Composites are a material comprised of two or more constituent materials that have different properties.

- The two materials work together to imrpove the mechanical, electrical, physical or chemical properties of the composite.

- Within the composite you can easily tell the different materials apart as they do not dissolve or blend into each other.

- Composites are an important material in an intensely competitive global market.

- New materials and technologies are being produced frequently for the design and rapid manufacture of high-quality composite products.

- Composites are replacing more traditional materials as they can be created with properties specifically designed for the intended application.

- As designers develop new products, they should always be aware of the materials available.

- In an effort to increase productivity and lose weight, carbon fiber parts are often glued together.

- The use of an epoxy adhesive rather than traditional fastening methods allows manufacturers to create more complex shapes quickly and easily.

- These materials and methods are being transferred to consumer products.

- The idea of creating composite materials is not new.

- One of the earliest examples is straw reinforced bricks, where the mud is the matrix and the straw is the reinforcement.

Form of Composites

- Composite material is made up of a matrix (binder or glue) in which a reinforcement (fibers, sheets or particles) is embedded.

- Composites take advantage of the directional properties of the reinforcement and gluing properties of the matrix.

Reinforcement

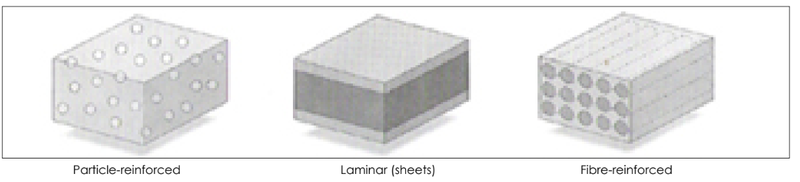

- The way in which the reinforcement is applied in a composite can happen in a number of ways, but generally there are three main categories:

- These fibres/sheets/particles can be made from textiles, glass, plastics, wood and carbon.

Laminar (Sheets)

- Consist of two or more layers bonded together, usually with an adhesive.

- Examples are:

- plywood

- laminated glass.

Fiber-reinforced

- Fibe-reinforced, which act as the reinforcing material.

- Examples are:

- glass

- carbon

- fibre

- reinforced concrete.

Particle-reinforced

- Contains particles, which act as the reinforcing material.

- There are many different forms of particulate composites.

- The particulates can be very small particles (< 0.25 microns), chopped fibers (such as glass), platelets, hollow spheres, or new materials such as bucky balls or carbon nano-tubes.

- Concrete is an example of particle-reinforced composites.

Matrix

- Most composites have two constituent materials: matrix (a binder), and a reinforcement.

- The reinforcement is usually much stronger and stiffer than the matrix, and gives the composite its good properties.

- The matrix holds the reinforcements in an orderly pattern.

- Because the reinforcements are usually discontinuous, the matrix also helps to transfer load among the reinforcements.

- The matrix can be made from:

- Polymers

- Polymer Matric Composites (PMC’s): such as thermoplastics and thermosetting plastics.

- Ceramics

- Ceramic Matrix Composites (CMC’s): such as concrete.

- Metals

- Metal Matrix Composites: such as titanium.

- Polymers

Processes of Making Composites

Weaving

- The act of forming a sheet-like material by interlacing long threads passing in one direction with others at a right angle to them.

Molding

- In open moulding, raw materials (resins and fiber-reinforcements) are exposed to air as they cure or harden.

- Open molding utilizes different processes, including hand lay-up, spray-up, casting, and filament winding.

- In closed-molding, raw materials (fibres and resin) cure inside a two-sided mold or within a vacuum bag (shut off from air).

- Closed-molding processes are usually automated and require special equipment, so they’re mainly used in large plants that produce huge volumes of material; up to 500,000 parts a year.

Pultrusion

- A continuous manufacturing process used to create composite materials that have a constant cross-section.

- Reinforcing fibers are saturated with a liquid-polymer resin and then pulled through a heated die to form a part.

Lamination

- Covering the surface of a material with a thin sheet of another material typically for protection, preservation or aesthetic reasons.

Composition and Structure of Composites

Concrete

- Concrete is made with water, Portland cement and aggregates (gravel, etc).

- The aggregate of coarse rock or gravel is embedded in a matrix of cement.

- The hardness of cement is increased significantly by adding gravel as reinforcing filler.

- Concrete is used in skyscrapers, bridges, sidewalks, highways, houses, dams etc.

Reinforced Concrete

- Where the rebar (metal rods) is the fibre and the concrete is the matrix.

- Skyscrapers, bridges, sidewalks, highways, houses and dams.

Engineered Wood

- Also called composite wood, man-made wood or manufactured board.

- Includes plywood, particle board and LVL.

Laminated Veneer Lumber (LVL)

- An engineered wood product that uses multiple layers of thin wood, oriented in the same direction, assembled with resins.

- Structural applications such as in buildings.

Plywood

- A sheet material manufactured from thin layers or “plies” of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another.

- Construction, internal (furniture, flooring, etc.) and exterior uses such as marine ply for boats.

Particle Board

- A material made from different sizes of wood chips and joined with glue.

- Furniture (such wardrobes, wall units, TV cabinets), shelving, toys, wall linings etc.

Fiberglass

- Stands of glass, formed into a matt and then covered in resin (polymer/thermoset plastic).

- Used in boats, pools, pipes, bathtubs, motors and car bodies.

Kevlar

- Para-aramid synthetic fiber covered in a resin.

- Used in body armor, high performance canoes or sports equipment, ropes, military applications etc.

Carbon-Reinforced Plastic

- Carbon fibers formed into a mat then covered in resin.

- Carbon fiber has played an important part in weight reduction for vehicles and aircraft.

- Used in high performance car racing, sports equipment (golf clubs, etc) and aviation (the Boeing Dreamliner).

Advantages and Disadvantages of Composite Materials

Advantages

Strength

- Per pound, composites are stronger than other materials such as steel.

- The two primary components of composites (fibers and resins) contribute to their strength.

- Fibers carry the load, while resins (matrix) distribute the weight throughout the composite part as required.

Lightweight

- Composites are light in weight compared to most woods and metals.

- Lower weight contributes to fuel efficiency in cars and airplanes. Lighter objects, ranging from utility poles to bridge decks, are easier to transport and install.

Resistance

- Composites resist damage from weather and harsh chemicals that can eat away at other materials.

- That makes them good choices for applications that face constant exposure to salt water, toxic chemicals, temperature fluctuations and other severe conditions.

Design Flexibility

- A wide range of material combinations can be used in composites, which allows for design flexibility.

- The materials can be custom tailored to fit unique specifications of each application.

- Composites also can be easily molded into complicated shapes.

- This offers designers, engineers and architects a freedom not typically found with other competing materials.

Durability

- Simply put, composites last!

- Structures made with composites have a long lifespan and require little maintenance.

- Many products made with composites, such as boats, have been in service for more than half a century.

Disadvantages

Delamination

- Since composites are often constructed of different ply layers into a laminate structure, they can “delaminate” between layers where they are weaker.

High Cost

- They are a relatively new material, and as such have a high cost.

- However, certain composites such as concrete have been around for a long time and are very cheap.

Complex Fabrication

- The fabrication process of composites is usually labor-intensive and complex, which further increases cost.

Lack of

- Lack of visual proof of damage: delamination and cracks in composites are mostly internal and hence require complicated inspection techniques for detection.

- This is especially a problem in buildings, where concrete is prone to crack around the small granules in the matrix.

- As these cracks are internal they can be very hard to spot early-on; possibly leading to failure or early renovations which waste resources.

Composite to Metal Joining

- Metals expand and contract more on variations in temperature as compared to composites.

- This may cause an imbalance at joinery and may lead to failure.

Availability

- The dissemination (distribution/availability) of composites globally is limited.